MxV Knock-Out Door

The Next Generation Knock-out Dock Door

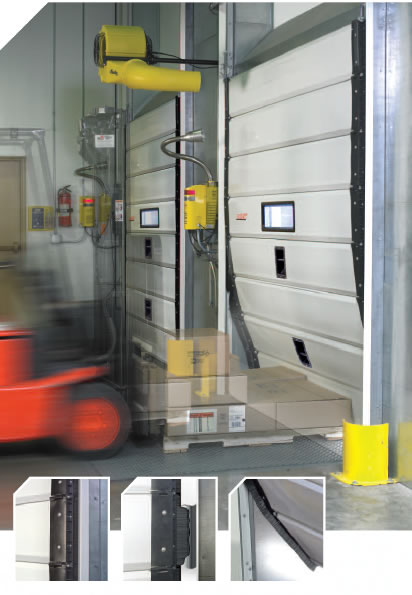

Today’s loading docks are handling more traffic than ever before. This higher volume of traffic has increased door damage, resulting in a loss of production and higher maintenance cost. MxV knock-out door design allows it to flex and release upon impact without damage to the door or track.

The brush that delivers value – MxV uses brush instead of rollers or pins. When riding in the PVC track the polypropylene brush won’t wear or fray. It’s washable and provides the best long term solution for sealing your dock door. More importantly, the brush allows the MxV to be knocked out and reset with ease.

SAVES TIME & MONEY

The causes are all too familiar – a misguided forklift truck, a spring not lubricated or cable jump – the result is that your dock door is out of service and you need to ship product. MxV knock-out door can eliminate this problem! MxV offers a flexible design that can be knocked out in either direction and reset by simply opening and closing the door. MxV keeps product moving at the loading dock door to improve logistics, productivity and efficiency.

SAFETY IS A MAJOR CONCERN

MxV provides a loading dock door that is consistently easy to operate compared with other sectional doors. MxV has no wearing parts so the door operation does not change even if the door gets hit or damaged. This ease of operation reduces worker fatigue that can be associated with sectional doors that are hard to operate due to damage on the panels, rollers or track

SAVES ENERGY... GO GREEN

MxV saves energy by offering the best long-term seal configuration available on the market today. The polypropylene brush seal helps to provide a better U–Factor (the lower the U–Factor, the greater a door’s resistance to heat flow and the better its insulating value) and eliminates costly side gaps that result from door damage, rubber seals that wear, improper installation or door size. This makes MxV the preferred door for food and cold storage applications. In addition to saving energy, MxV can also help the efficiency of the building’s refrigeration/heating systems by reducing load requirements during peak hours.

MxV Features

- Patented Polymer guide system – MxV knock-out door uses a brush instead of rollers, allowing for a continuous seal and a long lasting design that has the ability to knockout without costly door damage.

- High Performance – MxV’s rugged design resists damage from impact better than other knockout dock doors.

- Exclusive Self-Correcting Design – Simply open and close to re-set, no spring loaded rollers or pins to maintain.

- Flexible, 3” thick, insulated panels – MxV’s panels are lightweight and insulated, suitable for refrigerated loading docks.

MxV’s unique design helps to improve productivity on today’s busy loading docks

by reducing maintenance calls and avoiding costly downtime for door replacement or repair.

Product Video

Product Data

MxV DOOR

Dock Door

- Panels: 3”thick, UV Inhibited, Weather Resistant PVC

- Insulation: Closed Cell Polyurethane R-22

- Door sizes: Up to 10′ Wide X 12′ High

- Door Reset: Self Correcting – Resets by opening and closing the door

- Brush Seals: Nylon Header

- Side Brush Seals: Polypropylene

- End Cap: Injection molded plastic

- Track: PVC

- Knockout Capability: Full – top to bottom, inside or out

- Lock: Optional – Offers intruder security

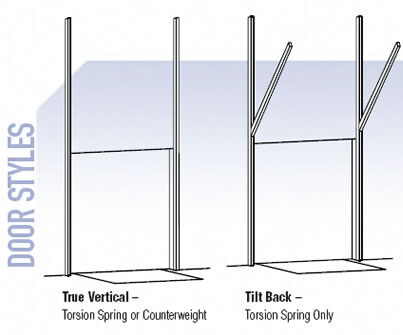

Torsion Springs

- Spring Cycle: 25 K (Standard)

- Door Cables: 5/32”- 7 x 19

galvanized steel - Shaft: 1” keyed hollow shaft

- Bearings: 1” UCF Precision Flange Bearing

Counterweight

- Counterweights: Round bar stock

- Door Cables: 5/32” – 7 x 19 galvanized steel

- Counterweight cables: galvanized steel includes cable cop and safety cog

- Shaft: 1″ keyed hollow shaft

- Bearings: 1″ UCF Precision flange bearing

Downloads